-

Kč

*precios sin IVA

The cable is originally wound on a roll of 3.5 km - there is the possibility of rewinding (a smaller section of the cable on another roll), the cost of the rewinding (the drum is included): 25 €

YOFC Z-XOTKtsdDb is a fiber optic cable designed for installation in telecommunication ducts. It is equipped with 96 G.652.D fibers (single mode) placed in 8 tubes. The tubes and fillers are twisted around a central reinforcing element, and the whole structure has additional circumferential reinforcement in the form of glass fibers. The tensile strength is 3.2 kN, making the cable suitable for mechanical pulling. The outer sheath, 1.1 mm thick, is made of HDPE. The outer diameter of the cable is 9.5 mm, and it weighs 80 kg/km.

The offered product is best suited for telecommunication ducts, especially in main routes. Thanks to its high tensile strength, it can be easily mechanically pulled over long distances. The use of G.652.D fiber is characterized by low attenuation.

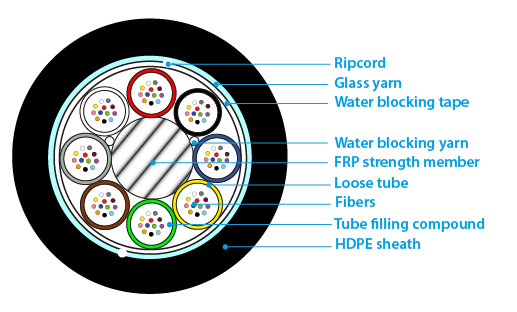

Cable construction

The cable is characterized by a multi-tube construction, where the tubes and fillers are twisted around a central reinforcing element - an FRP rod. This design makes the cable rigid, preventing the fibers from moving or shifting due to temperature fluctuations.

Furthermore, the entire structure has been additionally strengthened circumferentially with glass fibers to increase its tensile strength. Additionally, two ripcords have been placed in the sheath to facilitate its splitting.

Duct installation

The offered product is fully adapted for installation in telecommunication ducts. The HDPE sheath is abrasion-resistant and will not be damaged during pulling. The circumferentially placed glass fiber additionally protects the cable from rodent attacks.

The maximum tensile force of the cable is 3.2 kN, so there is no need to worry about damage during pulling. The multi-tube construction further enhances the durability of the optical fiber and facilitates installation work.

96 fibers (8 tube, 0 fillers)

The Z-XOTKtsdDb has 96 single-mode fibers of the G.652.D type placed in 8 tubes (12 fibers per tube). The outer diameter of the cable is 9.5 mm, and it weighs 80 kg/km.

The sheath is made of durable HDPE, with a thickness of 1.1 mm. The cable has been designed for outdoor installation, with a CPR class of Fca.

G.652.D (Singlemode) fiber

The fiber optic cable has been equipped with G.652.D single-mode fibers. This type of fiber is distinguished by low attenuation, which is ≤ 0.35 dB/km for the 1310 nm wave and ≤ 0.21 dB/km for the 1550 nm wave. These low losses have been achieved at the expense of less flexibility compared to G.657.A2 / G.657.B3 type fibers.

Thanks to these parameters, cables equipped with G.652.D fibers are best suited for use in main routes. In such applications, lower flexibility is not a disadvantage. Additionally, for transmissions over long distances, the overall attenuation will be significantly lower compared to other types of fibers.

Specifications

| YOFC Z-XOTKtsdDb 96 | |

| Fiber quantity | 96 |

| Fiber type | G.652.D |

| Maximum fiber attenuation at 1310 nm | ≤ 0,35 dB/km |

| Maximum fiber attenuation at 1550 nm | ≤ 0,21 dB/km |

| Total quantity of tubes and fillers | 8 |

| Fibers per tube | 12 |

| Central strength member | FRP rod |

| Water blocking material | Water blocking tape & yarn |

| Peripheral strength member | Glass yarns |

| Material of outer sheath | HDPE |

| Color of outer sheath | Black |

| Thickness of outer sheath | 1,1 mm |

| Number of ripcords | 2 |

| Cable diameter | 9,5 mm |

| Cable weight | 80 kg/km |

| Tensile strength | 3200 N |

| Minimum bending radius |

Static: 10x diameter Dynamic: 20x diameter |

| Colors |

1: red 2: green 3: blue 4: yellow 5: white 6: gray 7: brown 8: purple 9: aqua 10: black 11: orange 12: pink |

| Mechanical | |

|---|---|

| Tension |

Standard: IEC 60794-1-21-E1 Load: 3.2 kN Duration time: 1 min

|

| Crush |

Standard: IEC 60794-1-21-E3A Load: 1000 N / 100 mm Duration time: 1 min

|

| Impact |

Standard: IEC 60794-1-21-E4 R=300 mm, 10 J in 3 different places

|

| Repeat Bending |

Standard: IEC 60794-1-21-E6 Radius: 20 x diameter, 25 cycles Load 150 N

|

| Torsion |

Standard: IEC 60794-1-21-E7 Length under test: 1 m 10 cycles, turns: 180° Load: 150 N

|

| Water Penetration |

Standard: IEC 60794-1-22-F5 Sample length: 3 m Water height: 1 m, duration time: 24 h

|

| Temperatura Cycling |

Standard: IEC 60794-1-22-F1 Temperature -40° ~ 70° C Duration time: 12 h

|

Polski

Polski English

English Italiano

Italiano Español

Español Čeština

Čeština Српски

Српски Deutsch

Deutsch Ελληνικά

Ελληνικά Slovenský

Slovenský